Group

Telenco has been developing telecommunications networks for today and tomorrow since 1999. The Group designs, manufactures and exports reliable, sustainable solutions worldwide.

Markets

Telenco's offering adapts to the challenges of different telecoms markets. Our solutions are designed to meet the ever-evolving needs of fixed, mobile, private and data centre networks.

View allBrands

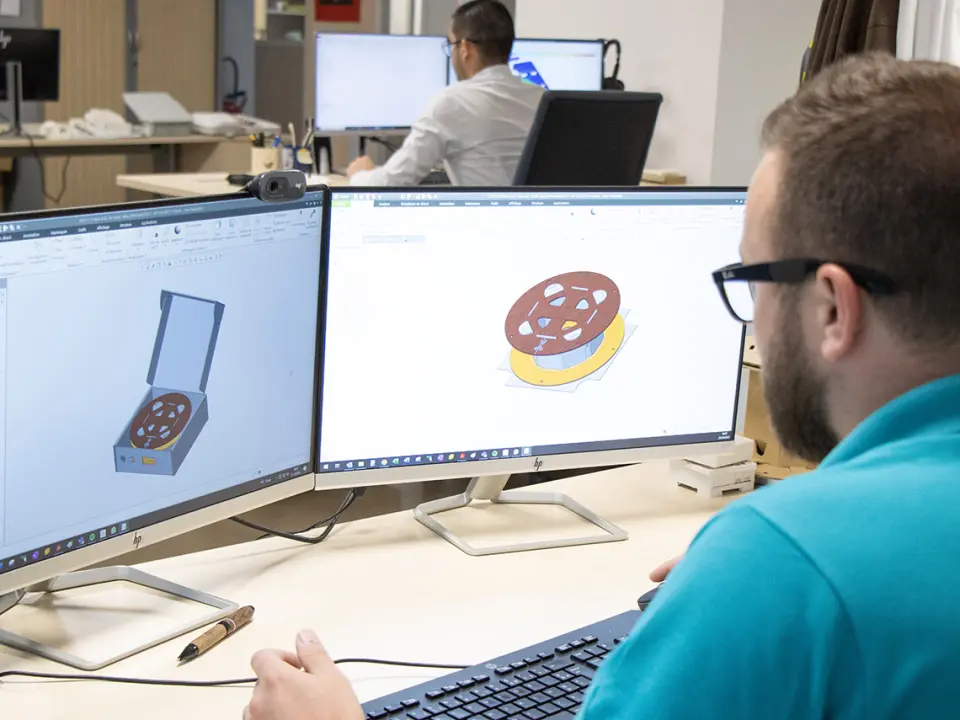

Telenco designs and manufactures telecommunications network equipment under 5 brands. Each has its own specialisation, but all are built around the same values: quality, sustainability and innovation.

Skills

Over the years, the Group has developed a wide range of complementary areas of expertise, enabling us to support our customers throughout their entire projects, from design to consulting, including internalising our manufacturing processes.

Careers

With over 650 employees on multiple continents, Telenco puts its collective strength and diversity to work for its customers. Help build networks by joining the Group!

Media

Keep up to date with all Telenco Group news.