As part of the Group’s environmental approach and with the stated aim of reducing its greenhouse gas emissions, Telenco carries out Life Cycle Assessment (LCA) calculations. This approach aims to evaluate the environmental impact of a product, taking into account its entire life cycle: from the extraction of raw materials to the end of its life. The aim is to be able to influence its environmental impact right from the design stage.

Ludovic Richard, R&D Project Manager at Telenco, and Ophélie Chamary, QSE-DD Coordinator for the Telenco Group, explain how this approach was implemented for the Modular Multi Enclosure Bracket (MMEB) product.

- Why did you design this product?

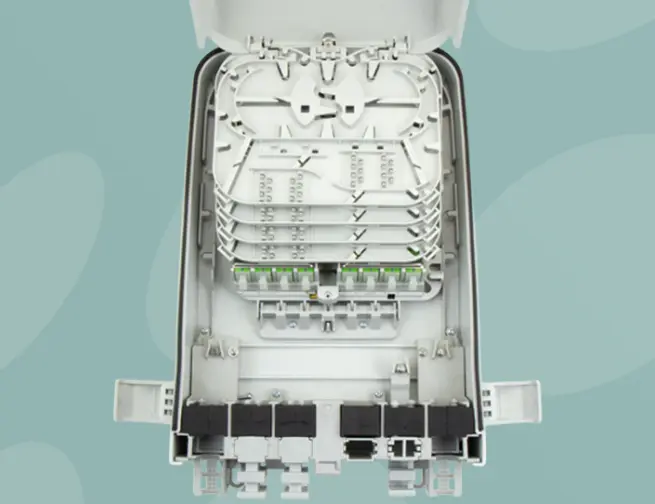

Ludovic: The MMEB is a mounting bracket that allows multiple installation of the various enclosures on the market. This product was specifically designed to meet the needs of the UK market. A competing product already exists on the market: in folded sheet metal with crimped inserts.

In order to be innovative, we have designed a modular product, made entirely of plastic, to meet the needs of different types of installation:

- on a MOBRA (Modular Bracket) in underground rooms on an articulated arm ;

- on a pole (wood, metal or composite) with a two-box configuration;

- on a pole (wood, metal or composite) with a three-box configuration.

Our product is distinguished by the recyclable materials of which it is made and by its various configurations.

- Why implement this type of approach at Telenco?

Ophélie: The LCA approach is linked to the overall strategy to reduce CO2 emissions. This approach is one of the elements that the Group uses to implement and maintain its SBTi commitments. Life cycle analyses are useful from an environmental point of view. They enable us to identify ways of improving the impact of our products on the environment and to specify the data in the Bilan Carbone calculated.

Ludovic: From an economic point of view, it allows us to reduce some production costs by cutting down on the use of materials.

- When does the LCA process come into play?

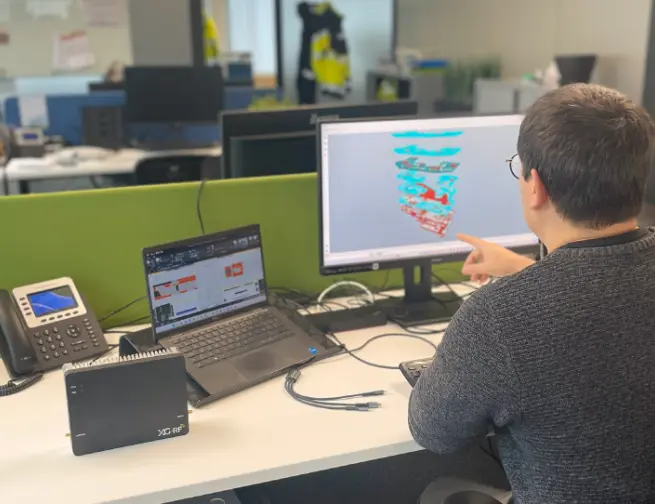

Ludovic: During the product design process, the design office carries out several development phases.

The LCA approach comes into play at two points in the design process. Firstly, when solutions are being sought, i.e. the stage during which R&D project managers develop product ideas. The various proposals are compared according to criteria of performance, quality, cost and environmental impact. If the product is made of several materials, we identify the one that emits the most CO2 and try to replace it with another that is just as effective but less polluting.

The analysis of the product life cycle is then used to validate industrialisation. This step corresponds to the launch of production tooling. This is when plastic injection moulds are made, for example.

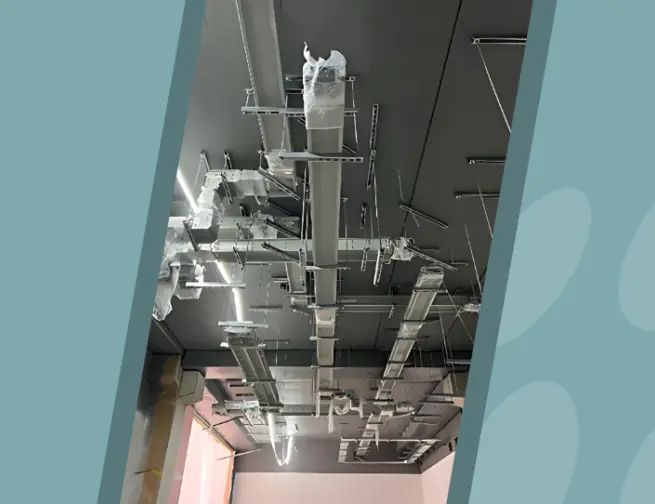

Ophélie: The product is designed in France. For the MMEB, the product is assembled in our unit in Portugal, so we chose to have the various parts that make up the product injected in Portugal. The aim is to maintain geographical proximity to the assembly site and reduce the impact of transport on the LCA.

- What factors are taken into account when calculating an LCA?

Ophélie: When we set up a Life Cycle Assessment process, we take into account the source of the raw materials that make up the product, where it is manufactured, how it is packaged, and so on. At Telenco, we have chosen to replace plastic bags with kraft paper bags. This allows us to use a material that has less impact on the environment during manufacture and is very easy to recycle. Packaging has a significant impact, since we can reduce CO2 emissions by up to 10%.

- Which departments are involved?

Ludovic: LCA is a global, collaborative approach that involves the company’s operational departments. The purchasing department is responsible for choosing the material with the best quality/cost/time ratio, etc. The QSE-DD department supports the design office by making calculations that will enable the project manager to make the best decisions. The design office analyses the performance and quality of the materials used.

The calculations made on products that have been in the catalogue for a long time are used to build up a database that can be used to compare components when creating new products. At Telenco, the LCA approach is defined as the driving force behind more responsible and effective innovation, encouraging teams to challenge themselves to design products that are more respectful of the environment.